Products / Nickel Alloys / Inconel / Inconel 800 Forgings

What is Incoloy 800-ALLOY 800/800AT/800H | Incoloy 800 Principal Features | Incoloy 800 Strength | Incoloy 800 Physical Properties | Incoloy 800 Price |

→ Nickel Alloys

→ PRODUCTS

We are industrial suppliers of Nickel Alloy 200 Products |

Please note: we may supply special diameters in small quantities at request

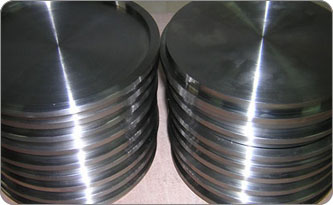

Hexion Steel LIMITED. also supply nickel alloy (super alloy) forging in various dimensions and grades. The forging products include block, ring, disc and hollow bar. Available size range: negotiation. Material: Nickel 200, Nickel 201, Monel 400, Monel 405, Monel k500, Inconel 600, 601, 617, 625, 718, Incoloy 800, 800H, 825, 825HT, Hastelloy C22, C276, Waspalloy, Invar 36, 42, Kovar, Alloy A286 Heat Treatment of Incoloy™ 825

Applications of Incoloy™ 825

Machinability of Incoloy™ 825

Workability of Incoloy™ 825

More useful informationStructural applications that require specific corrosion resistance or elevated temperature strength receive the necessary properties from nickel and its alloys. Some nickel alloys are among the toughest structural materials known. When compared to steel, other nickel alloys have ultrahigh strength, high proportional limits, and high moduli of elasticity. Commercially pure nickel has good electrical, magnetic, and magnetostrictive properties. Common nickel alloy families include: commercially pure nickel; binary systems, such as Ni-Cu, Ni-Si, and Ni-Mo; ternary systems, such as Ni-Cr-Fe and Ni-Cr-Mo; more complex systems, such as Ni-Cr-Fe-Mo-Cu (with other possible additions); and superalloys. Nickel content throughout the alloy families ranges from 32.5 to 99.5%. At cryogenic temperatures, nickel alloys are strong and ductile. Several nickel-base superalloys are specified for high-strength applications at temperatures to 2,000°F. High-carbon nickel-base casting alloys are commonly used at moderate stresses above 2,200°F. Alloy characteristics: Commercial nickel and nickel alloys are available in a wide range of wrought and cast grades; however, considerably fewer casting grades are available. Wrought alloys tend to be better known by tradenames such as Monel, Hastelloy, Inconel, Incoloy, etc. Casting alloys are identified by Alloy Casting Institute and ASTM designations. Wrought and cast nickel alloys are often used together in systems built up from wrought and cast components. The casting alloys contain additional elements, such as silicon and manganese, to improve castability and pressure tightness. Commercially pure nickels and extrahigh nickel alloys: Primary wrought materials in this group are Nickel 200 and 201, both of which contain 99.5% Ni. The cast grade, designated CZ-100, is recommended for use at temperatures above 600�F because its lower carbon content prevents graphitization and attendant ductility loss. Both wrought grades are particularly resistant to caustics, high-temperature halogens and hydrogen halides, and salts other than oxidizing halides. These alloys are particularly well suited for food-contact applications. Duranickel 301, a precipitation-hardened, 94% nickel alloy, has excellent spring properties to 600°F. During thermal treatment, Ni3AlTi particles precipitate throughout the matrix. This action enhances alloy strength. Corrosion resistance is similar to that of commercially pure wrought nickel. Nickel - Monel® - Inconel® - Incoloy® - Hastelloy® - Alloy 20 - Duplex - Olets® are the registered trademarks of their respective owners. |

|||||||||||||||||||||||||||||||||||||||||||||||||