Please note: we may supply special diameters in small quantities at request

UNS NICKEL MATERIAL GRADES |

| Nickel grade |

UNS |

Werkstoff |

DIN |

| INCOLOY 825 |

UNS N08825 |

24,858 |

NiCr 21 Mo |

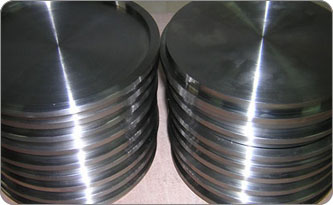

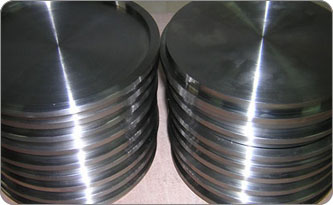

Hexion Steel LIMITED. also supply nickel alloy (super alloy) forging in various dimensions and grades. The forging products include block, ring, disc and hollow bar.

Available size range: negotiation.

User industries: Chemicals, Fats, & Fertilizers, Sugar Mills & Distilleries, Cement Industries, Ship Builders, Paper Industries, Pumps, Petrochemicals, Oil & Natural Gas Organization in terms of the specific materials, Technology, Finance & Personal.

Material: Nickel 200, Nickel 201, Monel 400, Monel 405, Monel k500, Inconel 600, 601, 617, 625, 718, Incoloy 800, 800H, 825, 825HT, Hastelloy C22, C276, Waspalloy, Invar 36, 42, Kovar, Alloy A286

Heat Treatment of Incoloy™ 825

- Anneal between 1700° and 1800°F (927° to 982°C)

- 1800°F (982°C) anneal maximizes softness and fine grain structure without sacrificing corrosion resistance

- 1725°F (941°C) optimum stabilizing temperature

- Rapid cool sections heavier than wire and sheet

- Remove surface contamination before annealing

Applications of Incoloy™ 825

- Equipment used to produce and handle phosphoric acid

- Equipment for handling refinery and coal-washing solutions and sludge

- Equipment used in the sulfuric acid pickling of copper and ferrous alloys

- Paper production industry

- Sour gas and oil well parts

- Flue gas scrubbers

Machinability of Incoloy™ 825

- Conventional machining in annealed condition

Workability of Incoloy™ 825

- Hot work between 1600° and 2150°F (871° and 1177°C)

- Final working between 1600° and 1800° (871° and 982°C) brings maximum corrosion resistance

- Air cool; faster cooling OK depending on size of section

- Well-powered, rigid equipment recommended for cold forming

| Incoloy 825 Forgings Application |

| Incoloy 825 Forgings Uses |

- Architecture and construction

- Aerospace

- Nuclear Power

- Fertilizers

- Valve & Pumps

- Petrochemical

- Motor industry

- Food and drink

- Electronics

- Transport and traffic

- Pulp and paper industry

- Medicine

- Energy industry

- Chemicals industry

- Nickel Alloy in Pulp and Paper

|

| Incoloy 825 Forgings Order & Packing Information |

| |

Min. Order: 10 Pieces (or please enquire for your customized order)

Trade Terms: FOB, CIF

Payment Terms: L/C, T/T

Packing: as per requirement

Place of Origin:JIANGSU, China

Means of Transport: Land, Ocean

Delivery Date: one or two week

Price: click here to check price

Package: in wooden crate with plastic caps on each end. |

More useful information

Chemical Analysis of ALLOY 600 (UNS N06600)

Inconel 600 , Nickelvac 600, Ferrochronin 600

MN |

P |

S |

Si |

Cr |

Ni |

Mo |

Cu |

Co |

Cb+Ta |

Ti |

Al |

Fe |

Other |

Other |

| .15 max |

1.0 max |

|

.015 max |

.5 max |

14.0 –17.0 |

72.0 min |

|

.5 max |

|

|

|

|

6.0 - 10.0 |

|

Size Range

Alloy 600 wire, bar, rod, forging, plate, sheet, tube, fastener and other standard forms are available.

Alloy 600 is a nickel-chromium alloy with excellent resistance to organic acids and is used extensively in fatty acid processing. The high nickel content of Alloy 600 provides good resistance to corrosion under reducing conditions, and its chromium content, resistance under oxidizing conditions. The alloy is virtually immune to chloride stress-corrosion cracking. It is also employed widely in the production and handling of caustic soda and alkali chemicals. Alloy 600 is also an excellent material for high-temperature applications requiring a combination of heat and corrosion resistance. The excellent performance of the alloy in hot halogen environments makes it a popular choice for organic chlorination processes. Alloy 600 also resists oxidation, carburization, and nitridation.

Corrosion resistance

Inconel 600 alloy are resistant to corrosion for a variety of corrosive media. Chromium alloy has better corrosion resistance than the Nickel 99.2 (alloy 200) and Ni 99.2 (alloy 201, a low-carbon) in the oxidation conditions. Meanwhile, the higher nickel content of the alloy make it has good corrosion resistance in reduction conditions and alkaline solution. And can effectively prevent the chlorine - iron stress corrosion cracking. Inconel 600 alloy have good corrosion resistance in acetic acid, acetic acid, YiSuan, stearic acid, organic acids, have medium corrosion resistance in inorganic acid. It has very good corrosion resistance in a nuclear reactor primary and secondary recycling of high purity water. The especially outstanding performance of Inconel 600 is resistant to dry chlorine and hydrogen chloride corrosion, the application temperature can be 650oC. At high temperatures, annealed and solution-treated state of the alloy has a very good antioxidant properties and high peel strength in air. Under high temperature, annealing state and solid solution processing mode of alloy has the very good antioxidant spalling performance and high strength in the air. The alloy resist ammonia nitrogen and permeability, carburizing atmosphere, but in REDOX conditions variations, alloy will be affected by the partial oxidation corrosion of medium (such as green death liquid)

Specifications

| Form |

Standard |

| Metal Type |

UNS N06600 |

| Bar |

ASTM B166 AMS 5665 Din 17752 |

| Wire |

|

| Sheet |

ASTM B168 AMS 5540 Din 17750 |

| Plate |

ASTM B168 AMS 5540 Din 17750 |

| Tube |

ASTM B167 |

| Pipe |

ASTM B167 |

| Fitting |

ASTM B366 |

| Forging |

ASTM B564 Din 17754 |

| Weld Wire |

FM 82/ ERNiCr-3 |

| Weld Electrode |

FM 182/ ENiCrFe-3 |

| Din |

2.4816 |

Nickel - Monel® - Inconel® - Incoloy® - Hastelloy® - Alloy 20 - Duplex - Olets® are the registered trademarks of their respective owners.