→ Nickel Alloys

→ PRODUCTS

We are industrial suppliers of Nickel Alloy 200 Products

We are industrial suppliers of Nickel Alloy 200 Products |

|

Home / Products / Nickel Alloys / 254 SMO / ASTM A403 254 SMO Insert Weldolet

254 SMO (UNS S31254)

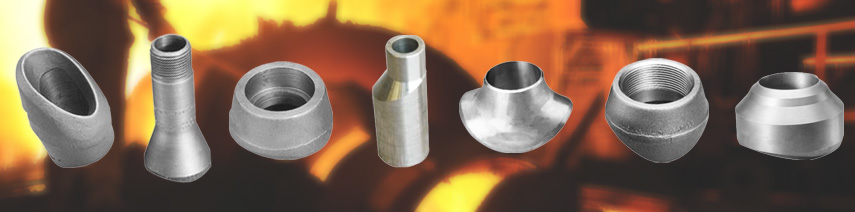

We are one of the renowned manufacturers of insert weldolet, offering a range that is made from high quality material. These are made in compliance with the industry standards and are available in several specifications as per the demands. Our range is widely used in diverse industries and is popular for its features like corrosion resistance, high durability and long working life.

ASTM A403 254 SMO Insert Weldolet

Specifications

| Standards |

Designation |

| ASTM |

A 403 |

| ASME |

SB 403 |

ASTM A403 254 SMO Insert Weldolet Inventory Stock at factory rate:-

Dimensions

Specifications

| Alloy |

Common Name |

Related Specifications |

Tensile Strength |

Proof Stress |

Elongation |

| British |

European |

United States |

| Alloy 254 |

254SMO |

|

1.4547 |

ASTM A479/A473,

/A240 S31254

F44 |

655

[95] |

305

[44.2] |

35 |

| Specifications of Alloy 254 |

- Alloy 254 to MLA-MPS-254-BAR

- ASTM A479 Bar UNS S31254

- ASTM A276 Bar UNS S31254

- ASTM A182 Forgings UNS S31254 F44

- ASTM A240 Plate S31254

|

Chemical Specification of Alloy 254

| Elements |

C |

Cr |

Fe |

Mo |

Mn |

N |

Ni |

Nb |

P |

S |

Si |

V |

| Minimum |

|

19.5 |

REMAINDER |

6.0 |

|

0.18 |

17.5 |

|

|

|

|

|

| Maximum |

0.02 |

20.5 |

|

6.5 |

1.0 |

0.22 |

18.5 |

|

0.03 |

0.01 |

0.8 |

|

Basic Properties of Alloy 254- Mechanical Properties

| 0.2% Proof Stress (N/mm2 )[ksi] minimum |

300 [43.5] |

| Ultimate Tensile Strength (N/mm2) [ksi] minimum |

650[94.2] |

| Elongation (%) minimum |

35 |

| Hardness (HBN) |

270 max |

| Reduction of Area(%) minimum |

50 |

Physical Properties of Alloy 254

| Density (Kg.m-3) |

8000 |

| Magnetic Permeability |

<1.05 |

| Young’s Modulus (N/mm2) |

200 x 103 |

| Specific Heat 20°C (J.Kg-1.°K-1) |

500 |

| Electrical resistance, 20°C (µ.O.m) |

0.85 |

| Thermal conductivity, 20°C (W.m-1.°K-1) |

13.5 |

Alloy 254 Features

- High strength compared to 316L and 317L austenitic stainless steels

- Excellent ductility and impact strength at both ambient and sub-zero temperatures

- Non-magnetic

- Higher resistance to abrasion, erosion and cavitation erosion than 316 and 317 stainless

- Listed in MR-01-75 for sour service oilfield applications

Machining Advice of Alloy 254 - Hot worked and precipitation hardened

| Operation |

Cutting Speed m/min (ft/min) |

Feed Rate

mm/rev (in/rev) |

Depth of cut mm (in) |

| Milling |

18 (58) |

0.13-0.25 mm/tooth

0.005-0.010 in/tooth |

0.2-3.0 (0.007-0.12) |

| Drilling 6.4mm(1/4") dia |

250rpm |

0.075(0.003) |

|

| Drilling 12.7mm(1/2") dia |

250 rpm |

0.125(0.005) |

|

| Drilling 25.4mm(1") dia |

150 rpm |

0.28(0.011) |

|

| Turning - Roughing |

30 - 45 ( 100 - 150 ) |

0.4-0.5 (0.015-0.020) |

2.5 (0.1) |

| Turning - Finishing |

50 - 60 ( 165 - 200 ) |

0.13-0.20 (0.005-0.008) |

0.5 (0.02) |

| Tooling |

Milling/Turning: Carbide (SANDVIK GC 235, SECO T25M)

Drilling: HSS, point angle 118°, chisel angle 120° |

Alloy Comparisons

| Alloy Comparisons |

S20910 |

S32205 |

N05500 |

S31254 |

FERRALIUM 255-SD50 |

| (0.2% Proof Strength, N/mm2) |

420 |

510 |

690 |

325 |

610 |

Corrosion Rate (mm.y-1)Seawater |

<0.01 |

<0.01 |

<0.18 |

<0.01 |

<0.01 |

Corrosion Rate (mm.y-1)10% sulphuric acid at 80°C |

0.7 |

0.4 |

0.1 |

<0.15 |

<0.15 |

Corrosion Rate (mm.y-1) Boiling 50% nitric acid |

0.18 |

<0.15 |

0.15 |

<0.15 |

<0.15 |

| Wear Properties related to Hardness (HRC) |

RC27 |

RC25 |

RC20 |

RC27 |

RC27 |

KEY Features of Alloy 254

- Resistant to crevice corrosion in seawater

- Excellent corrosion resistance in seawater and concentrated halide environments

- High resistance to stress corrosion cracking

- Good resistance to erosion corrosion

- Excellent ductility and impact strength at both ambient and sub-zero temperatures

- Low magnetic permeability

Main Export Market

- Eastern Europe

- North America

- Mid East/Africa

- Central/South America

- Asia

- Western Europe

- Australasia

- UAE

Sales Locations

U.A.E,

Oman,

Saudi Arabia,

Qatar,

Bahrain,

Egypt,

Turkey

Singapore,

Thailand,

Malaysia

Indonesia

Poland

Italy

Portugal

Spain

Brazil

Chile

Venezuela

Costa Rica

USA

Canada

Angola

Sri Lanka

Russia

|