→ PRODUCTS

We are regular suppliers from China for ANSI/ASME B16.9 Butt weld Stub End |

Home / Products / Butt-Welding Fittings / ANSI/ASME B16.9 Butt weld Stub End We have in store for our clients, a quality assured range of stubend long & short fittings that are in compliance with the industry accepted standards and norms. These fittings are hot dip galvanized, epoxy coated and electro polished for durability purpose. We also provide these fittings along with mill test certificate as per EN B16.9 to suit the quality conscious approach of our clients.ANSI/ASME B16.9 Butt weld Stub EndDesigned in accordance with B16.9 (ASA) or MSSSP-43. Available in all sizes and material grades.

Dimensions

The dimensions are in millimeters STUB ENDS - Ansi and MSS SP-43 dimensions

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

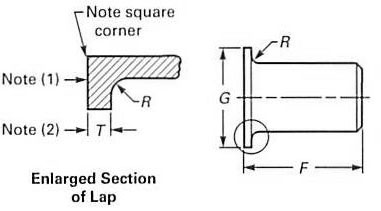

DIMENSIONAL TOLERANCES - STUB ENDS |

||||||

| For all fittings | Stub Ends | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Indide Ø at End | Wall Thickness t / t1 |

O.D. of Lap G | Fillet Radius of Lap - R | Overall Length. - F |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | +0 -1 | +0 -1 | 2 |

| 3 a 3 1/2 | 1 | 1,6 | less | +0 -1 | +0 -1 | 2 |

| 4 | +2 -1 | 1,6 | than | +0 -1 | +0 -2 | 2 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | +0 -1 | +0 -2 | 2 |

| 8 | 2 | 1,6 | of nominal | +0 -1 | +0 -2 | 2 |

| 10 | +4 -3 | 3,2 | tickness | +0 -2 | +0 -2 | 2 |

| 12 to 18 | +4 -3 | 3,2 | +0 -2 | +0 -2 | 3 | |

| 20 a 24 | +6 -5 | 4,8 | +0 -2 | +0 -2 | 3 | |

| 26 a 30 | +7 -5 | 4,8 | ||||

| 32 a 48 | +7 -5 | 4,8 | ||||

STUB ENDS - Weights

| NPS inches |

STUB ENDS | |||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Approximate weights in kg, density 8 kg/dm3 | ||||

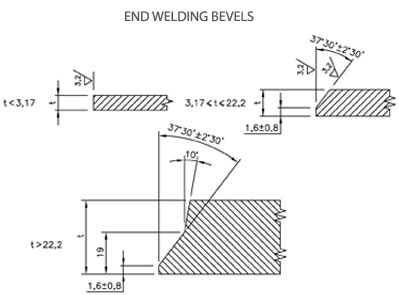

STUB ENDS - End welding bevels

| NOMINAL PIPE SIZE (Inches) | NB | OD | THICKNESS | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 80 |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 15NB | 21.30 | 1.65 | 2.11 | __ | 2.41 | 2.77 | 3.73 |

| 3/4 | 20NB | 26.70 | 1.65 | 2.11 | __ | 2.41 | 2.87 | 3.91 |

| 1 | 25NB | 33.40 | 1.65 | 2.77 | __ | 2.90 | 3.38 | 4.55 |

| 1 1/4 | 32NB | 42.20 | 1.65 | 2.77 | __ | 2.97 | 3.56 | 4.85 |

| 1 1/2 | 40NB | 48.30 | 1.65 | 2.77 | __ | 3.18 | 3.68 | 5.08 |

| 2 | 50NB | 60.30 | 1.65 | 2.77 | __ | 3.18 | 3.91 | 5.54 |

| 2 1/2 | 65NB | 73.00 | 2.11 | 3.05 | __ | 4.78 | 5.16 | 7.01 |

| 3 | 80NB | 88.90 | 2.11 | 3.05 | __ | 4.78 | 5.49 | 7.62 |

| 3 1/2 | 90NB | 101.60 | 2.11 | 3.05 | __ | 4.78 | 5.74 | 8.08 |

| 4 | 100NB | 114.30 | 2.11 | 3.05 | __ | 4.78 | 6.02 | 8.56 |

| 5 | 125NB | 141.30 | 2.77 | 3.40 | __ | __ | 6.55 | 9.53 |

| 6 | 150NB | 168.30 | 2.77 | 3.40 | __ | __ | 7.11 | 10.97 |

| 8 | 200NB | 219.10 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 12.70 |

| 10 | 250NB | 273.00 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 15.09 |

| 12 | 300NB | 323.80 | 3.96 | 4.57 | 6.35 | 8.38 | 10.31 | 17.48 |

| 14 | 350NB | 355.60 | 3.96 | 6.35 | 7.92 | 9.53 | 11.13 | 19.05 |

| 16 | 400NB | 406.40 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 | 21.44 |

| 18 | 450NB | 457.00 | 4.19 | 6.35 | 7.92 | 11.13 | 14.27 | 23.83 |

| 20 | 500NB | 508.00 | 4.78 | 6.35 | 9.53 | 12.70 | 15.09 | 26.19 |

| 22 | 550NB | 559.00 | 4.78 | 6.35 | 9.53 | 12.70 | __ | 28.58 |

| 24 | 600NB | 610.00 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 30.96 |

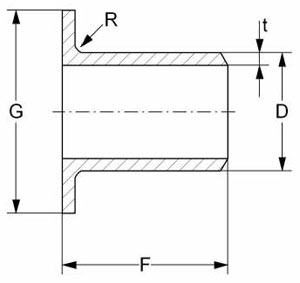

STUB ENDS SHORT LENGTH ASTM A403/A815 ASME B16.9

Facing: 125-250 RMS (smooth finish)

welded version = w

= s seamless execution

| Nominal | Schedule | D | t | G | F | R. Max. | kg / St. | |

|---|---|---|---|---|---|---|---|---|

| 1/2 " | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 " | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 " | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 " | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 " | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 " | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 " | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 " | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 " | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 " | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 " | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 " | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 " | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 " | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |

| 40s | 9.53 | 14.29 | w | |||||

| 14 " | 10s | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 | w |

| 40s | 9.53 | 17.15 | w | |||||

| 16 " | 10s | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 | w |

| 40s | 9.53 | 20.41 | w | |||||

| 18 " | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 | w |

| 20 " | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 | w |

| 24 " | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 | w |

Main Export Market

- Eastern Europe

- North America

- Mid East/Africa

- Central/South America

- Asia

- Western Europe

- Australasia

- UAE

U.A.E,

Oman,

Saudi Arabia,

Qatar,

Bahrain,

Egypt,

Turkey

Singapore,

Thailand,

Malaysia

Indonesia

Poland

Italy

Portugal

Spain

Brazil

Chile

Venezuela

Costa Rica

USA

Canada

Angola

Sri Lanka

Russia

|

||||||||||||||||||||||||